Factories can be a very hazardous working environment, especially if a business does not maintain their factory floor safety. From slips, trips and falls, to accidents involving vehicles at work, there’s a range of risks and hazards that employers need to be protecting their employees against, which is why we have decided to share our top tips on exactly how employers can create and maintain a high level of safety within their factory.

Risk Assessment

The first and most practical step for creating a safe factory floor is conducting a risk assessment, to identify all hazards, in order to then identify the steps and procedures you need to carry out to mitigate these risks and hazards.

To identify the hazards within your workplace, you can firstly check out the HSE’s website, where they have provided useful information for risk assessments across a wide range of sectors. You can also simply walk around your factory in the areas your employees use and note anything you feel poses or might pose a risk. Finally, you could also look through your previous accident books and records, to gather information on problems that have occurred in the past.

Whilst conducting this assessment, you can also assess the fire safety risks within your factory. This 5 step checklist from gov.uk is excellent to use to assess whether or not your factory has a high level of fire safety.

Working at Heights

If you identified risks and hazards within your factory relating to working at heights, it is important that you now begin to plan and execute methods to mitigate these risks.

The law surrounding Working at Height provides guidance that you should ensure all workers can get safely to and from where they work at height. Line markings can be used on staircases leading to elevated platforms; a bold yellow strip can be marked out on the edge of each step, to aid all employees, particularly visually impaired workers, preventing trips and falls.

Vehicles at work

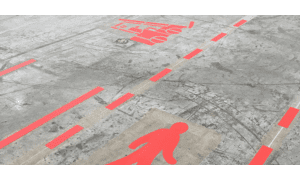

If vehicles are operated within your factory in the same space where your employees operate and walk around line markings can also help to mitigate any accidents involving vehicles at work.

It is important that you put measures in place to keep people and vehicles apart within your factory and this can be achieved through creating visible designated walk ways for pedestrians and marked routes and hatched areas for vehicles to follow and park. These line markings will help to not only help create a high level of safety on your factory floor, but they will help to improve vehicle traffic flow and the production and movement of products within your factory.

Clear Signage

If you identify any safety hazards whilst conducting your risk assessment or issues relating to your fire safety, clear signage can mitigate these risks and issues.

Bold signs and worded line markings can be used within your factory to help highlight hazardous areas to employees, alerting them not to enter this area or to keep the area clear.

Pedestrian walkways and Fire Exit signage can also be marked out with line markings, to highlight the Fire Exit routes within your factory, so all employees know where to go in the case of a fire.

Train Staff

Another method that your business can conduct to create a high level of safety on your factory floor is through training your staff.

Through conducting training sessions that cover the safety guidelines you wish to implement or already have implemented within your factory, you can ensure that all employees know how to work safely and without risks to health.

Good housekeeping

A simple method to maintain factory floor safety, but one that is often overlooked by businesses is good housekeeping.

Through creating a procedure that outlines what should be done in the case of a spillage and how this should be cleared, you can easily reduce the risk of slips and trips within your factory. You must ensure that all employees are trained on this procedure, as an effective procedure will not be effective if your employees are unaware of its existence.

Regular Maintenance and Visual Inspections

The final method to maintain a high level of safety within your factory is visual expectations. Similar to the activities you should have carried out during your risk assessment, you can simply walk around your factory in the areas your employees use, to check that all of the procedures and methods you have implemented within your factory are still working effectively.

It is common for factory floor health and safety markings to wear and tear over time, due to this space being used on a daily basis by both pedestrians and heavy duty vehicles. We offer a service, where we can top-up your health and safety markings, to ensure they remain bright, bold and effective at reducing risks and hazards.

Along with checking the condition of your floor markings, you should also check the condition of the floor itself, whether vehicles and pallets have been stored in their designated areas and whether workers are continuing to use their designated pedestrian walkways. If any of the above are not being complied with, we advise you put methods in place to fix the issues and conduct refresher training for all employees, educating them once again on the health and safety procedures and methods you have in place.

We also advise that your business keeps a record of when these maintenance checks and visual inspections have taken place and by whom.